How to Set the Right Manufacturing Targets

Setting the right targets for your company is SO important because without goals your plant will run with no direction or vision. You’ll have some workers really working hard to bring home that bacon and some workers just relaxing because management has not set a vision for the plant. It’s a disaster! When you learn how to set the correct targets, you won’t believe the impact it will have on the productivity of your plant.

[bctt tweet=”“Setting the right targets is SO important because without goals your plant will run with no direction or vision.”” username=”@lightningsolve”]

Tom, where do I start? How do I choose targets?

Maybe your company has been running in free-fall mode so long you can’t even see the firing range, let alone the target! Never fear – I’m here to guide you to that perfect bullseye. The first thing I do when I go to a plant to help set targets is make question diagrams. I’ll typically make one question diagram based around Time, and another question diagram based around the Products themselves. Which leads us to query…

What is a question diagram?

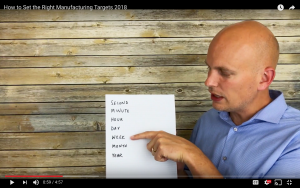

I’m glad you asked! Be sure to check out today’s video for clear visual examples of question diagrams. We started with a Time-based Question Diagram. You’ll want to look at the most productive moments of your business and list them like so:

Second

Second- Minute

- Hour

- Day

- Week

- Month

- Year

Basically, you’re searching for the very most productive second, of the most productive minute, of the most productive hour, day, week, month and year. Notice how you always start with the smallest thing first? That’s how you eat an elephant – one small bite at a time. (Not that I’ve actually tried that, but it’s what “they” say.) You’re also going to look for the mirror-image WORST counterpart seconds, minutes, days and so on.

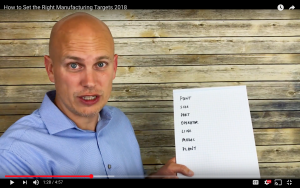

Now we’re going to talk about a Product-based Question Diagram. Again, we want to start with the smallest thing and work toward the biggest:

Point

Point- Side

- Part

- Operator

- Line

- Model

- Plant

So here we’ll start seeking the best point, on the best part, on the best side, from the best operator, made on the best machine, in the best line, on the best model, from the best plant.

The question diagram is designed to help you find the problems-solver’s best friends: CONTRAST.

[bctt tweet=”“The question diagram is designed to help you find the problem solver’s best friend – and that is CONTRAST.”” username=”@lightningsolve”]

Now what do we do with all this information?

Simply put, you’ve figured out that Mr. Fast (whom you can call Speedy Gonzales if you want) is your best operator. And he happens to work on line 3, and you notice that 2 p.m. is his best time of day. Now that you know this, you can compare it to the other operators and teach them to work as efficiently as Mr. Fast. Your job is to train all of your employees to perfect their process to the point that everyone’s numbers match Mr. Fast’s numbers. If Mr. Fast can do it, then with the right training, even Droopy can do it! And you’ve just made your first successful target. Congrats!

A few more managing tips on being Grand Goal Master

First of all, be sure your goals are realistic. You never want to set your goals to high that it actually discourages your employees.

[bctt tweet=”“First of all, be sure to set realistic goals. Don’t set your goals so high that it actually discourages your employees.”” username=”@lightningsolve”]

You also have to be extremely careful with incentives. The major problem with incentives is – when, and how are you going to STOP giving them? If you make the offer to an employee, such as, “If you meet your targets this week we will give you a free ipad”, when are you going to stop handing out that incentive? People will surely get used to the perks and then start underperforming until the incentives return.

Don’t let people tell you, “Well, our employees only make $10 an hour. You can’t expect them to manage scrap too!” ONLY $10 an hour?! First of all, a lot of my international engineering friends make $6.50 per DAY and they have college degrees! Secondly, this is crazy thinking because by standardizing their work we are actually making their jobs easier. They don’t have to think as much to get positive results.

Get rid of all the magic in your plant

Wait! I know this sounds a little glum at first, but, before you trash all those Lucky Charms, let me explain! Make sure there are no “secret recipes” that only 1 person knows. If there are aspects of a recipe that require special talent, that’s fine, but make sure everything else is standardized work. Every single day, you’re only going to pour 1 cup of flour into this recipe for success. Sure, you may have to tweak your recipe occasionally with weather changes, ambient temperature variances, humidity, barometric pressures – but you still have the same recipe.

Then you want to standardize the problem-solving on each line. Pick your best problem-solver and ask him or her questions to find out how they learned to tweak the recipe.

[bctt tweet=”“Pick your best problem-solver and ask him or her questions on how they learned to tweak the recipe.”” username=”@lightningsolve”]

And guess what? That’s your new standardized-work Gold Standard for problem-solving! Set your targets and figure out the work standards needed to reach them, then drive your plant so your employees never play around with the standards.

Troubleshooting those elusive targets

There have been a couple of facilities where I’ve needed to be a little creative on how I found their particular targets. So I’ve done Time Studies. Meaning I did the work myself and timed myself doing the work. Sometimes I think, in a perfect world, if I had a robot doing this, how long would it take?

The ideas I’ve given you today work for developing scrap targets, efficiency targets, production targets, employee pay raise, and countless other targets. With all those targets in your sights, you’ll be a regular Annie Oakley!

If this blog has helped you at all, be sure to try out a few of my videos as well. This way you’ll never miss out on any of my keys to mastering manufacturing! If you find yourself needing help setting the right targets for your company, I also do consulting, so feel free to get in touch. Let me know in the comments below if you have any other bright ideas on how to set targets in your workplace.

Thanks for dropping in! Hope you have a fantastic day!